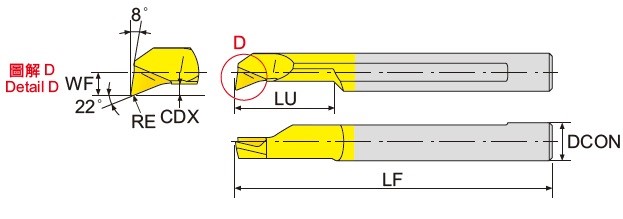

Batang Bor Karbida Profil Kecil GP_R

Batang Bor Karbida Profil Kecil -GP_R

|

產品型號 |

最⼩ |

刃⾓R |

最⼤加⼯ |

柄部直徑 |

可使⽤ |

標準 |

⼯作 |

|

GP1RL104R005 |

1 |

0.05 |

0.2 |

3 |

4 |

39 |

0.5 |

|

GP1.5RL106R01 |

1.5 |

0.1 |

0.3 |

3 |

6 |

39 |

0.7 |

|

GP2RL110R005 |

2.1 |

0.05 |

0.5 |

3 |

10 |

39 |

0.8 |

|

GP2RL110R01 |

2.1 |

0.1 |

0.5 |

3 |

10 |

39 |

0.8 |

|

GP2RL105R015 |

2.1 |

0.15 |

0.5 |

3 |

5 |

39 |

0.8 |

|

GP2RL110R015 |

2.1 |

0.15 |

0.5 |

3 |

10 |

39 |

0.8 |

|

GP3RL110R005 |

3.1 |

0.05 |

0.7 |

3 |

10 |

39 |

1.3 |

|

GP3RL115R01 |

3.1 |

0.1 |

0.7 |

3 |

15 |

39 |

1.3 |

|

GP3RL122R01 |

3.1 |

0.1 |

0.7 |

3 |

22 |

50 |

1.3 |

|

GP3RL110R02 |

3.1 |

0.2 |

0.7 |

3 |

10 |

39 |

1.3 |

|

GP3RL115R02 |

3.1 |

0.2 |

0.7 |

3 |

15 |

39 |

1.3 |

|

GP3RL122R02 |

3.1 |

0.2 |

0.7 |

3 |

22 |

50 |

1.3 |

|

GP3RL115R05 |

3.1 |

0.5 |

0.7 |

3 |

15 |

39 |

1.3 |

|

GP4RL115R01 |

4.1 |

0.1 |

0.8 |

4 |

15 |

50 |

1.7 |

|

GP4RL122R01 |

4.1 |

0.1 |

0.8 |

4 |

22 |

50 |

1.7 |

|

GP4RL110R02 |

4.1 |

0.2 |

0.8 |

4 |

10 |

50 |

1.7 |

|

GP4RL115R02 |

4.1 |

0.2 |

0.8 |

4 |

15 |

50 |

1.7 |

|

GP4RL122R02 |

4.1 |

0.2 |

0.8 |

4 |

22 |

50 |

1.7 |

|

GP5RL122R01 |

5.1 |

0.1 |

1.2 |

5 |

22 |

50 |

2.1 |

|

GP5RL130R01 |

5.1 |

0.1 |

1.2 |

5 |

30 |

60 |

2.1 |

|

GP5RL115R02 |

5.1 |

0.2 |

1.2 |

5 |

15 |

50 |

2.1 |

|

GP5RL122R02 |

5.1 |

0.2 |

1.2 |

5 |

22 |

50 |

2.1 |

|

GP5RL130R02 |

5.1 |

0.2 |

1.2 |

5 |

30 |

60 |

2.1 |

|

GP6RL115R02 |

6.1 |

0.2 |

1.4 |

6 |

15 |

50 |

2.8 |

|

GP6RL122R02 |

6.1 |

0.2 |

1.4 |

6 |

22 |

50 |

2.8 |

|

GP6RL130R02 |

6.1 |

0.2 |

1.4 |

6 |

30 |

60 |

2.8 |

|

GP8RL115R02 |

8.1 |

0.2 |

1.6 |

8 |

15 |

60 |

3.8 |

|

GP8RL122R02 |

8.1 |

0.2 |

1.6 |

8 |

22 |

60 |

3.8 |

|

GP8RL135R02 |

8.1 |

0.2 |

1.6 |

8 |

35 |

75 |

3.8 |

|

GP10RL135R02 |

10.1 |

0.2 |

2 |

10 |

35 |

75 |

4.8 |

-

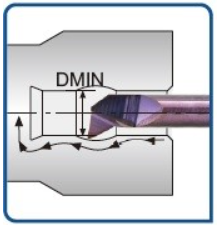

Cocok untuk pembuatan dan pemrosesan komponen kecil presisi seperti peralatan medis profesional, elektronik, kimia, dan industri.

1. Batang bor karbida kecil mengadopsi bodi pemotong karbida penuh untuk secara efektif menekan getaran pemrosesan.

2. Lapisan AlTiN karbida yang disemen dengan partikel ultra-halus untuk meningkatkan daya tahan alat.

3. Desain diameter mikro bermanfaat untuk persyaratan pemrosesan pemotongan, penyalinan, dan chamfering benda kerja di lubang sempit.

4. Memberikan akurasi pemesinan yang presisi dan penyelesaian permukaan yang baik.